2019 the TroPro trade exh…

Release Time:2016/12/07 troubleshooting Browsing Times:1095

There are three cases.

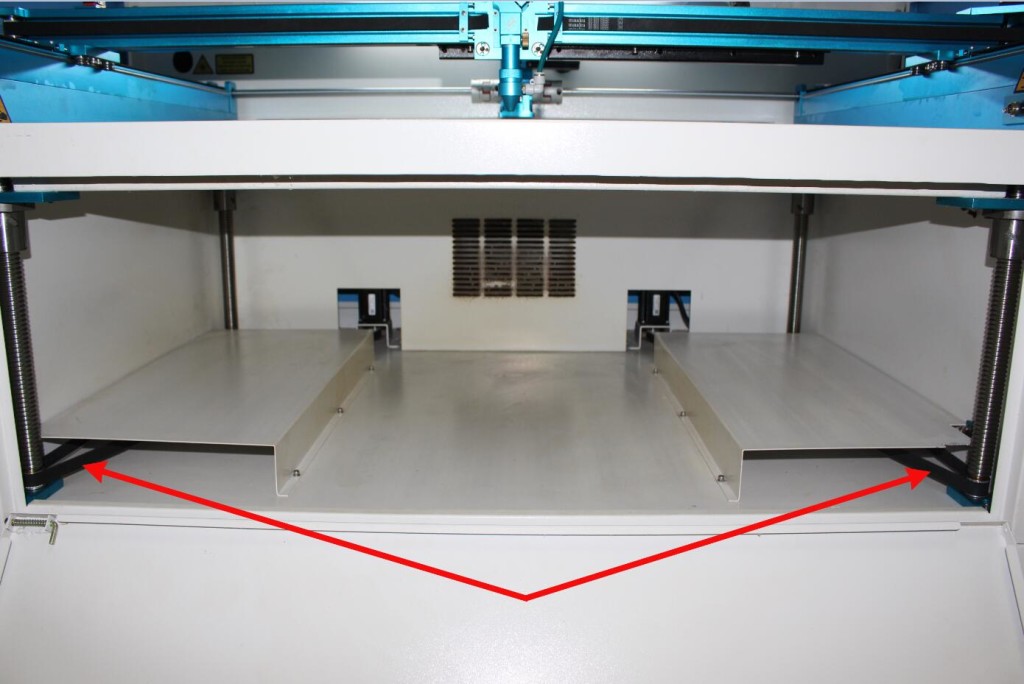

1. Two sides of the working table are not of the same height.

Turn off the whole machine power, manually pull one of the belts of Z axis so as to adjust the up and down of the working table height of this side and calibrate the level in this way. Shown as below:

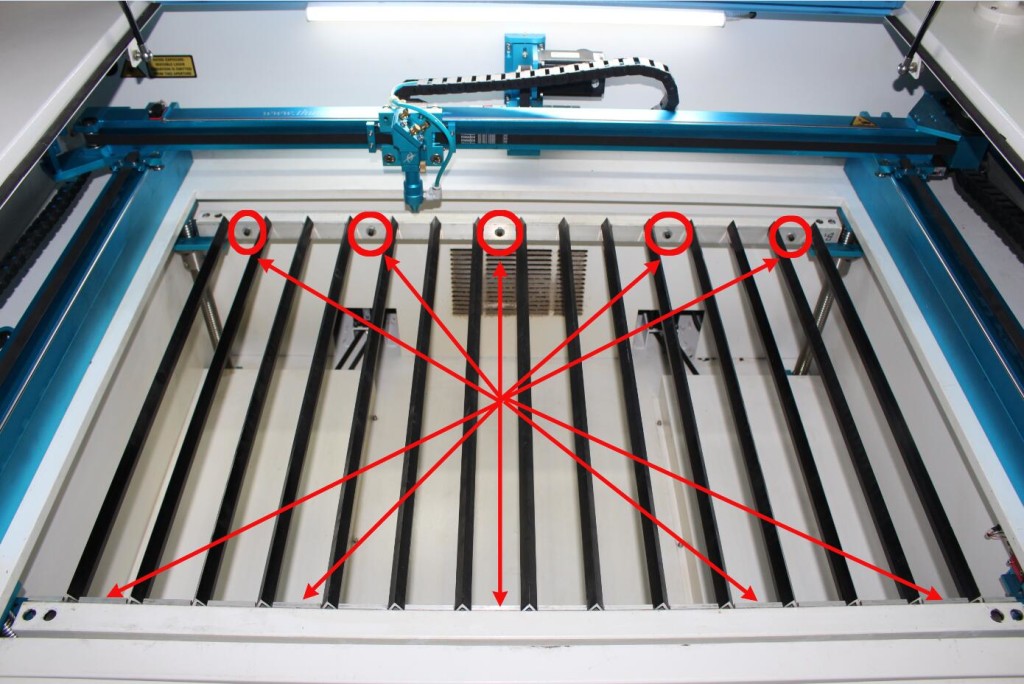

2. If it’s one of the four corners that is of different height from the other three corners, use method 2.

As shown above, by adjusting these screws you can fine adjusting the support frame of the knife table so as to calibrate height of one corner.

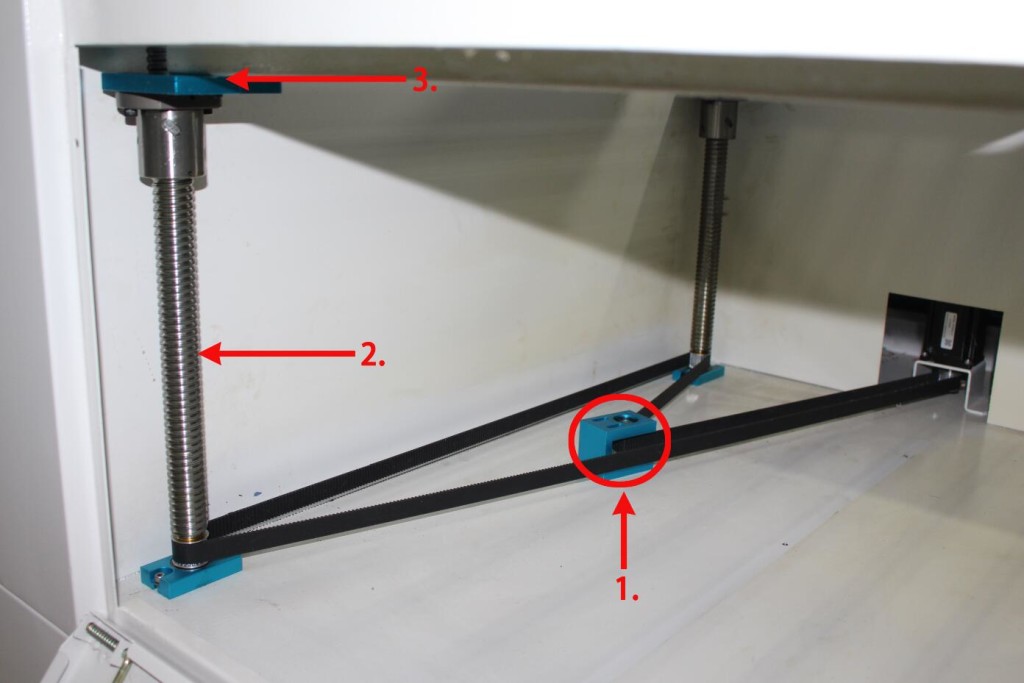

3. If neither of above two methods can solve the problem, please use method 3. But it’s much more difficult. Please handle it carefully.

1. Loosen the screws of the fixed module. The belt will be loose accordingly.

2. Rotate the lead screws to calibrate the table height of this corner. (PS: rotate it clockwise, table in this corner will go up; turn it anticlockwise, table will go down)

3. Working table of this corner will go up or down when you rotate the lead screw in different directions.

If the problem still cannot be solved, please contact with our tech team:tech@thunderlaser.com.